Description

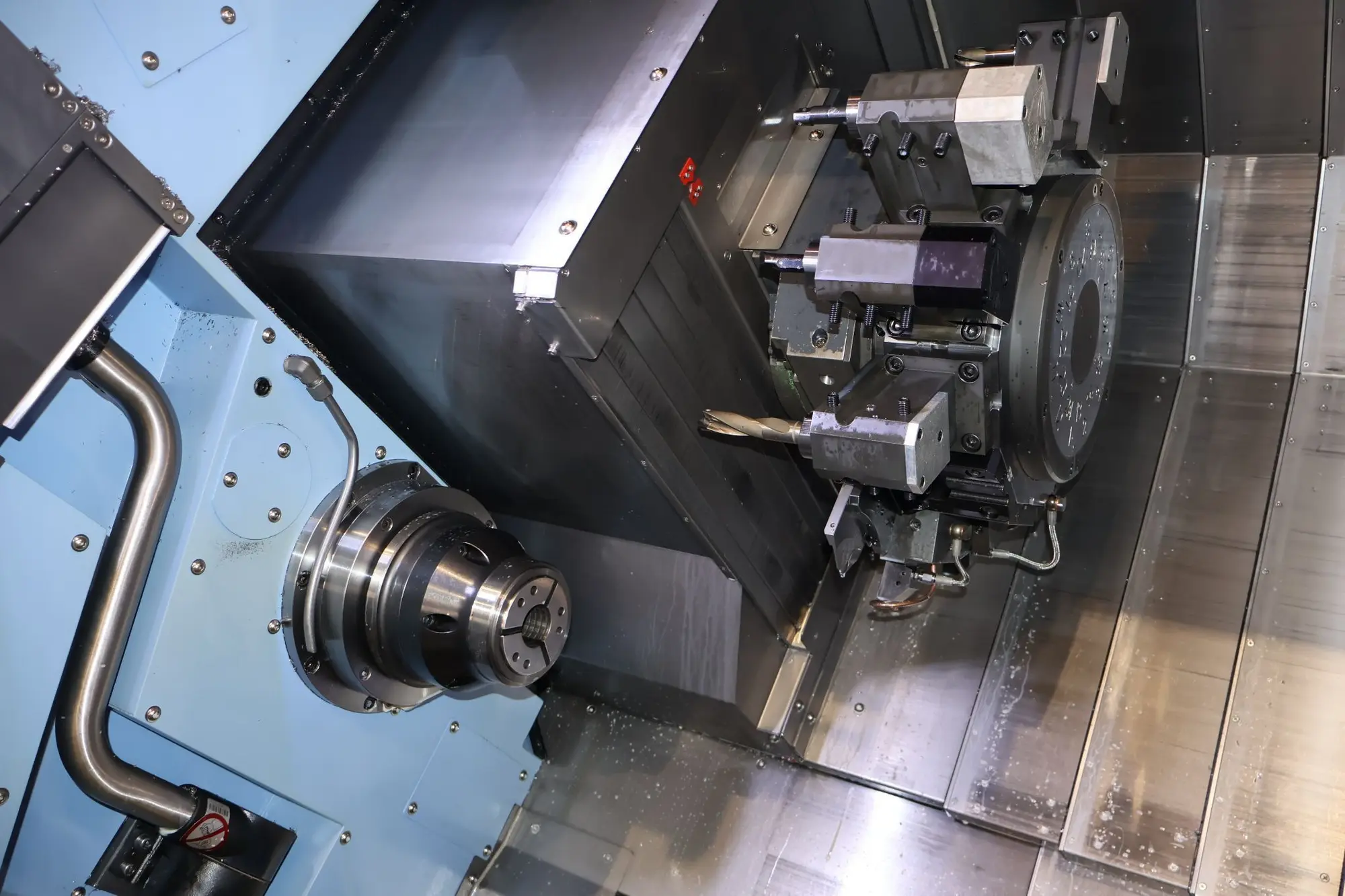

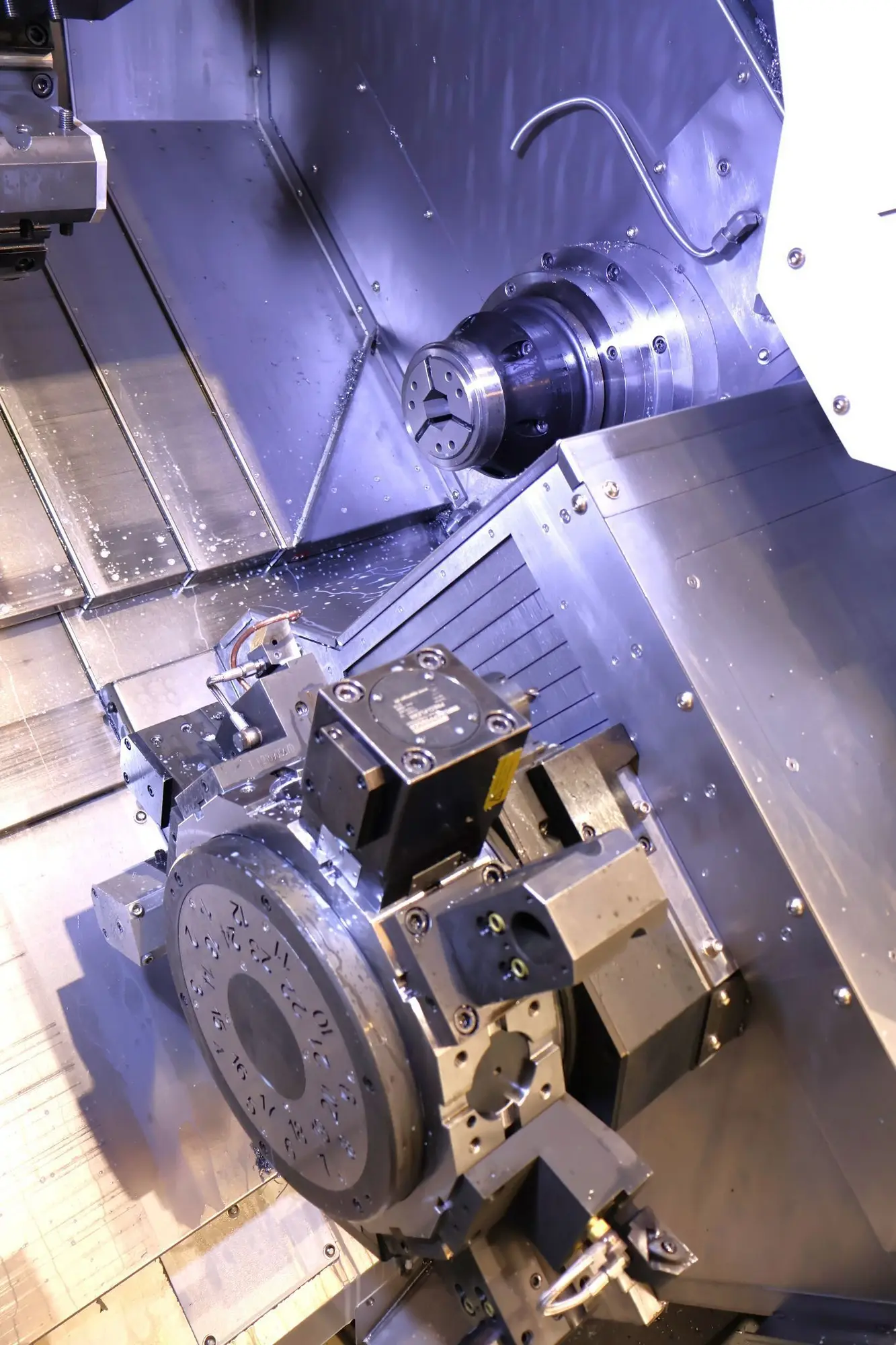

High-precision twin-spindle, twin-turret turning center offering full Y-axis capability, live tooling, and synchronized sub-spindle machining. This Doosan Puma TT1800SY is equipped with a FANUC OiTP control, dual 30 HP spindles, and includes premium options such as an Edge Technologies Rebel 80SE barloader, programmable parts unloader, and high-pressure coolant system. A well-maintained, low-hour multitasking lathe ready for continuous production.

Specifications

- Manufacturer / Model / Year: Doosan Puma TT1800SY, 2021

- Control: FANUC OiTP with Doosan EZ Guide i Conversational

- Type: 5-Axis Twin-Spindle, Twin-Turret CNC Turning Center

- Swing Over Bed: 9.05″

- Max Cutting Diameter: 9.05″

- Max Cutting Length: 38.5″

- Distance Between Spindles: 38.5″

- Bar Capacity (Main/Sub): 2.625″

- Spindle Nose (Main/Sub): A2-6

- Spindle Motor Power (Main/Sub): 30 HP each

- Spindle Speed (Main/Sub): 5,000 RPM

- Turrets: Two (upper with Y-axis), each 12 stations (BMT55 type)

- Live Milling: Yes — 5,000 RPM, 7.5 HP motor

-

Travels:• X-axis: 6.5″ (upper), 7.5″ (lower)• Y-axis: 3.93″• Z-axis: 27.5″ (upper), 28.3″ (lower)• C-axis: Full contouring on both spindles (0.001° indexing)

- Rapid Traverse (X / Y / Z): 787 / 295 / 1,575 IPM

- Machine Weight: approx. 18,000 lbs

Equipped With

- FANUC OiTP CNC with EZ Guide i Conversational Programming

- Edge Technologies Rebel 80SE Servo Barloader

-

Live Tool Holders:• (4) X-axis Eppinger Preci-Flex rotary holders• (2) Z-axis Eppinger Preci-Flex rotary holders

- Miscellaneous static and live holders

- Royal QG65 collet chucks (main + sub)

- Programmable parts unloader/conveyor (sub)

- Parts catcher (main)

- Turbo rear-discharge chip conveyor with M-code

- 145 PSI high-pressure coolant pumps

- Tool setter

- Auto door

- 3-color tower light

- Way lube oil skimmer

- Solid box-way Meehanite cast-iron bed

Usage:

- Power On 9,126 hrs | Run Time 2,061 hrs | Cutting Time 890 hrs

Condition

Used, in excellent mechanical and cosmetic condition. Low-hour machine with premium tooling, automation, and coolant options — ideal for complex, lights-out turning and milling operations.