Description

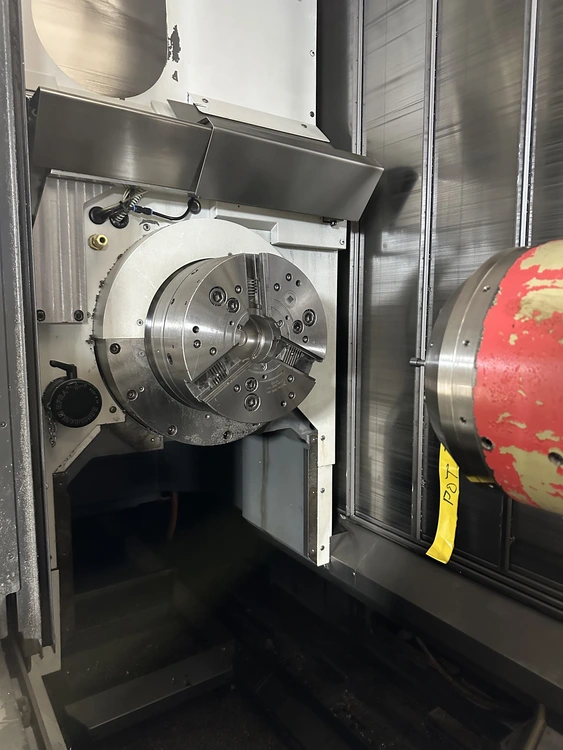

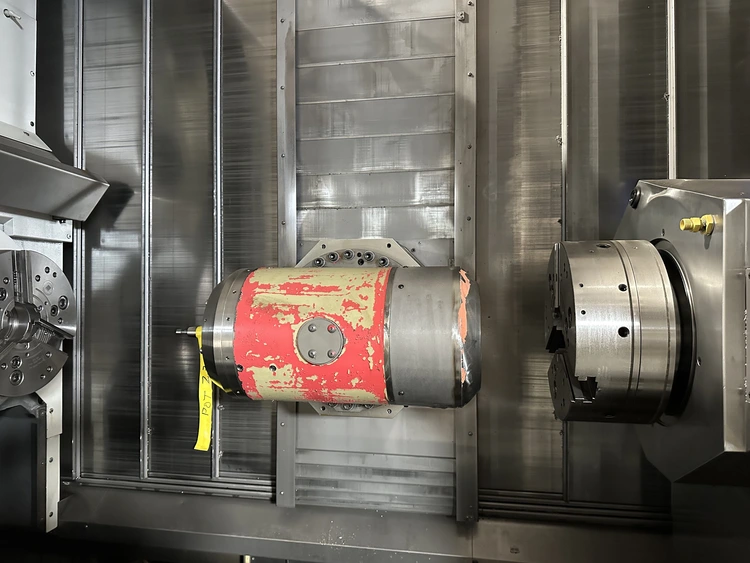

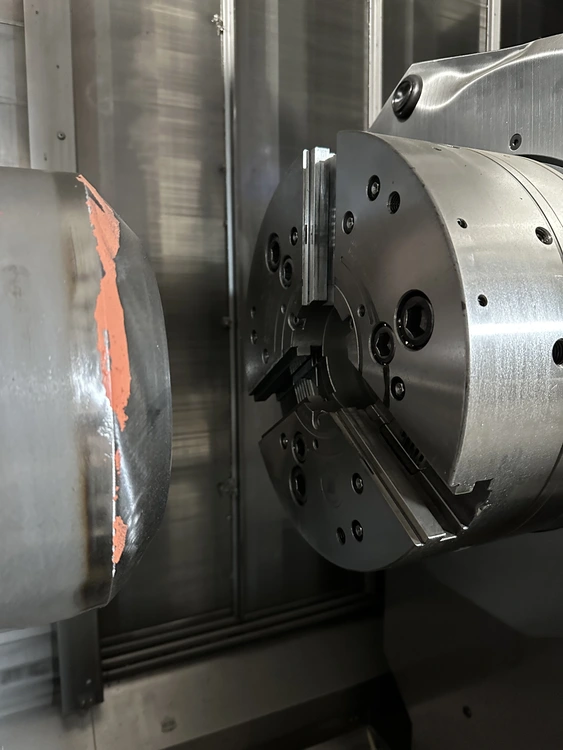

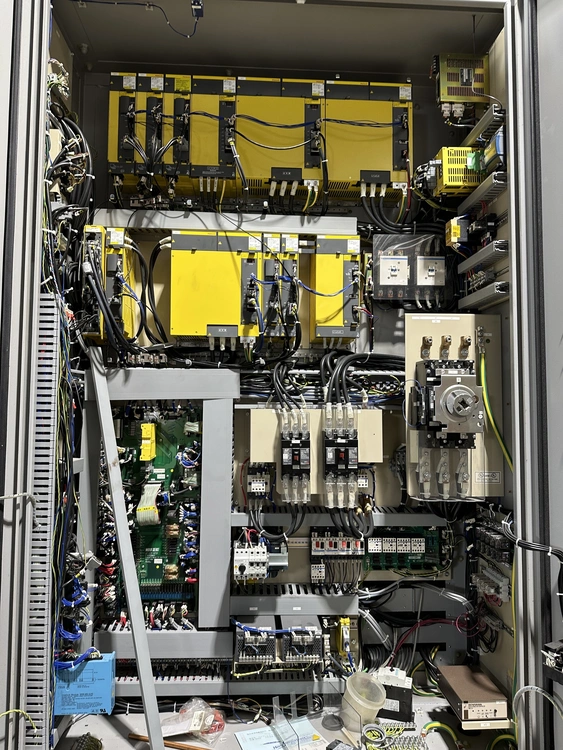

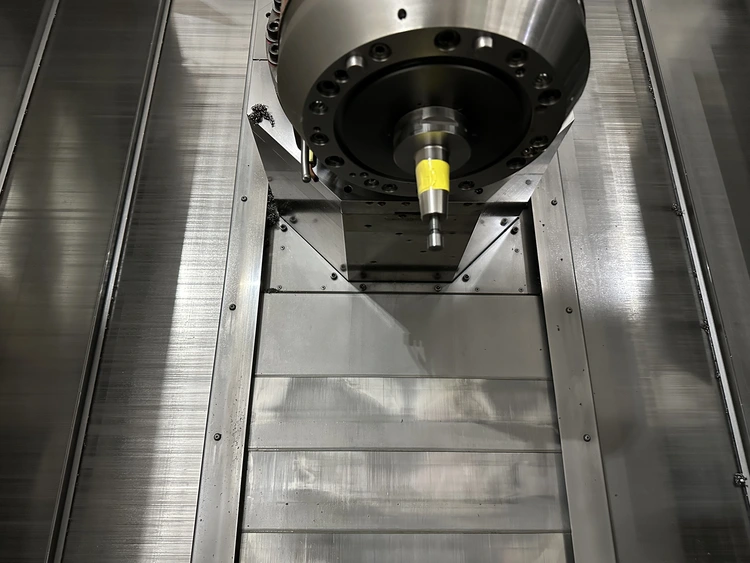

Premium double-spindle, B-axis multitasking center designed for full 5-axis simultaneous machining and one-setup production of complex parts. The NT4300DCG/1500S features twin 12″ chucks, 240-tool magazine upgrade, high-speed Capto C6 milling spindle, and Mori Seiki’s integrated MSX 711 IV CNC control — combining turning, milling, and drilling operations in a single platform.

Specifications

- Manufacturer / Model / Year: Mori Seiki NT4300DCG/1500S, 2008

- Type: 5-Axis CNC Multitasking Lathe

- Control: Mori Seiki MSX 711 IV (Fanuc-based)

- Swing Over Bed: 28.7″

- Max Turning Diameter: 28.7″/15.7″

- Max Turning Length: 58.9″

- Distance Between Spindles: 73.3″

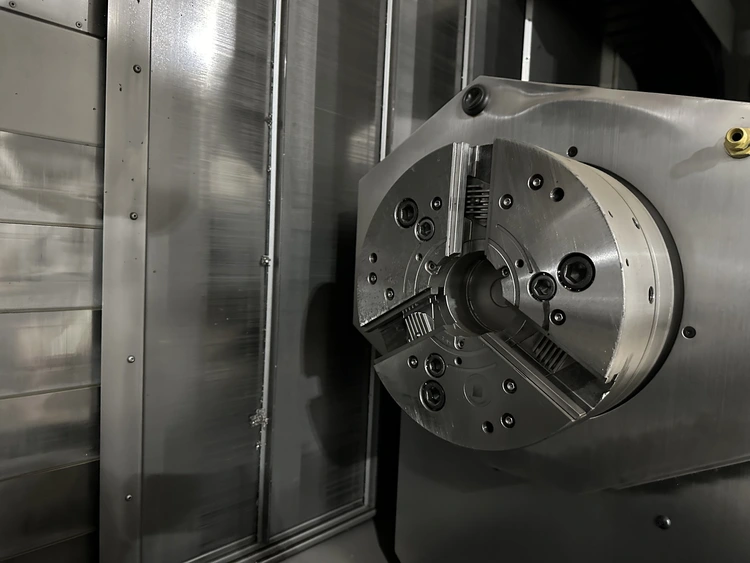

- Chuck Size (Main/Sub): 12″ / 12″

- Spindle Nose: A2-8 (both)

- Spindle Bore Diameter: 4.1″

- Bar Capacity: 3.5″

- Spindle Speeds (Main/Sub): 2,500 RPM

- Spindle Power (Main/Sub): 40 HP each

- B-Axis Milling Spindle: 12,000 RPM, 24.7 HP, Capto C6 taper, 0.0001° indexing

- Tool Changer: 240-tool automatic magazine (upgraded)

-

Travels:• X1: 29.5″ Z1: 61″• X2: 7.7″ Z2: 60″• Y-Axis: ±8.3″• W-Axis (Sub): 63″

- Rapid Traverse Rates: Up to 1,968 IPM (X/Z) and 1,181 IPM (Y)

- Weight: ≈ 62,250 lbs

- Footprint: ≈ 21′ L × 10′ W × 9′ H

Equipped With

- New chip conveyor (recent upgrade)

- 240-tool automatic changer (expanded capacity)

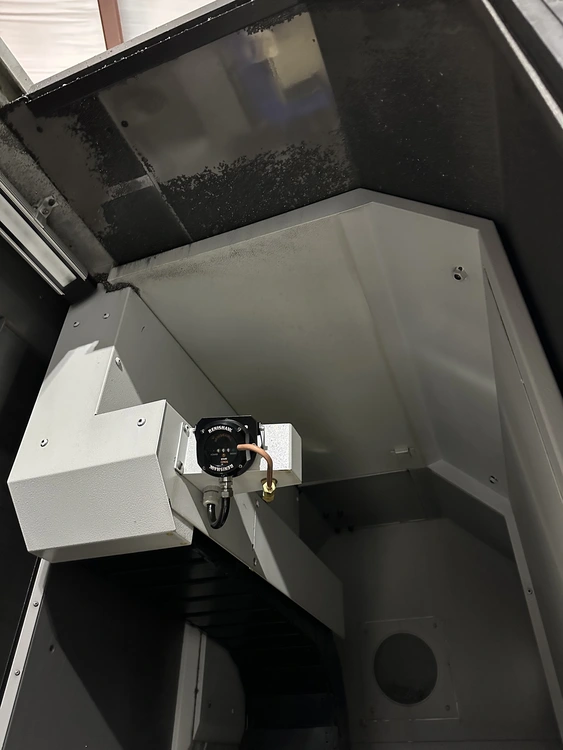

- Tool presetter

- High-pressure coolant system

- Renishaw probing system

- Full B-axis milling spindle

- Twin 12″ chucks, C-axis on both spindles

Condition

Used and in excellent mechanical condition. Clean, upgraded machine offering high-rigidity dual-drive design (DCG), complete 5-axis capability, and extensive tooling capacity—ready for complex multitasking production.