Description

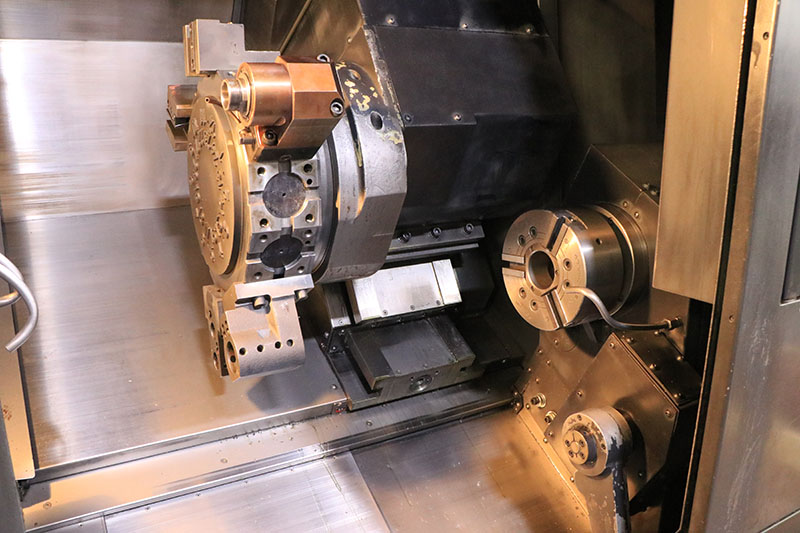

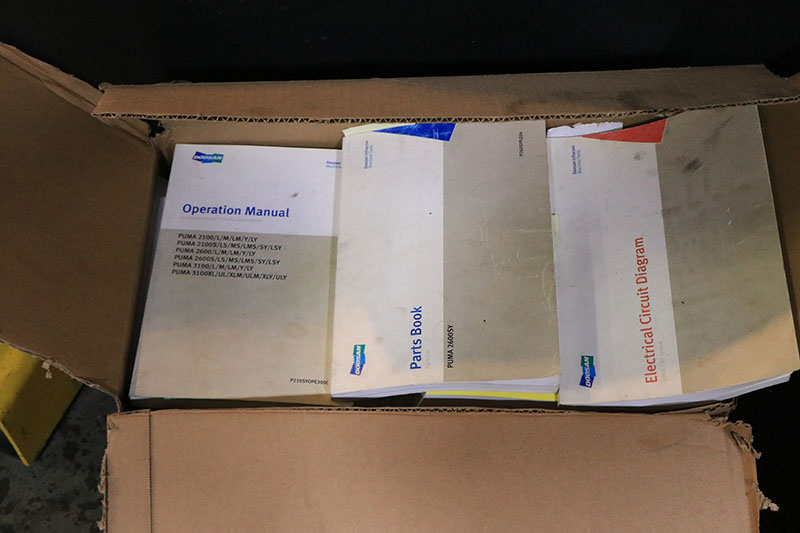

Powerful and versatile multi-axis turning center designed for high-precision, complex part machining in a single setup. The Doosan Puma 2600SY features twin spindles, Y-axis capability, and live tooling for complete part machining from raw bar to finished component. Combining robust construction with advanced Fanuc 31iT CNC control, it delivers excellent accuracy, rigidity, and reliability for demanding production environments.

Technical Specifications

- Manufacturer: Doosan

- Model: Puma 2600SY

- Year: 2010

- Type: Multi-Axis CNC Turning Center

- Control: Fanuc 31iT CNC Control

- Swing Over Bed: 30.7″

- Swing Over Front Door: 26.8″

- Swing Over Carriage: 24.8″

- Maximum Turning Diameter: 14.8″

- Maximum Turning Length: 29.92″

- Distance Between Spindle Noses: 43.46″

- Main Spindle Bore: 3.38″

- Main Spindle Nose: A2-8

- Main Spindle Speed: 4,000 RPM

- Main Spindle Motor (30 min rating): 30 HP

- Sub-Spindle Speed: 6,000 RPM

- Sub-Spindle Motor (30 min rating): 20 HP

- Sub-Spindle Bore: 2.44″

- Bar Capacity: 3.03″ (main)

- X-Axis Travel: 10.23″

- Z-Axis Travel: 32.67″

- Y-Axis Travel: ±2.065″ (total 4.13″)

- B-Axis (Sub-Spindle) Travel: 32.6″

- Rapid Traverse (X/Z): 1,181 IPM

- Rapid Traverse (Y): 394 IPM

- C-Axis Resolution: 0.001°

- Live Tool Spindle Speed: 5,000 RPM

- Live Tool Motor Power (15 min): 7.5 HP

- Live Tool Torque: 34.7 ft-lbs

- Tooling Type: BMT 65P

- Turret Stations: 12 (24 indexing positions)

- OD Tool Size: 1.0″

- Boring Bar Diameter: 2.0″ main / 1.0″ sub

- Floor Space (L×W): 153″ × 74″

- Machine Height: 85″

- Weight: Approx. 14,220 lbs

Equipped With

- Fanuc 31iT CNC control

- 10″ 3-jaw hydraulic chuck (main spindle)

- 8″ 3-jaw hydraulic chuck (sub-spindle)

- Tool setter

- 12-station turret with 24-position indexing

- Live and static toolholders (included)

- Parts catcher and parts conveyor

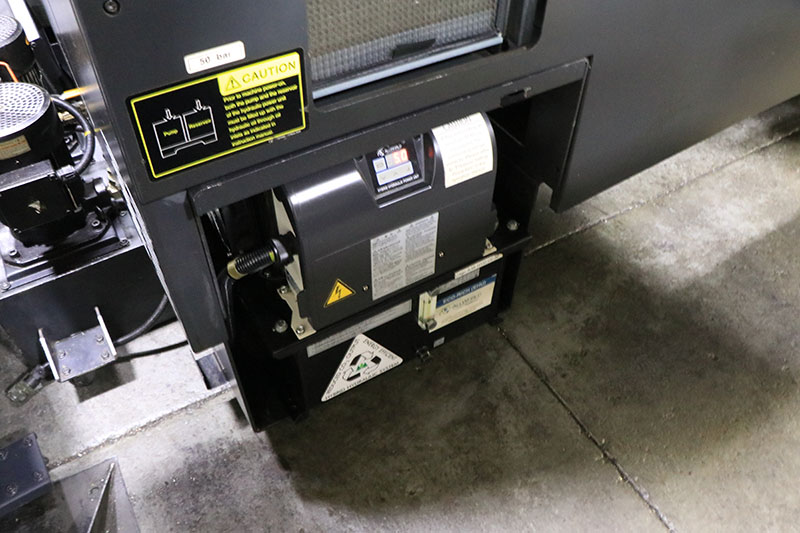

- Chip conveyor

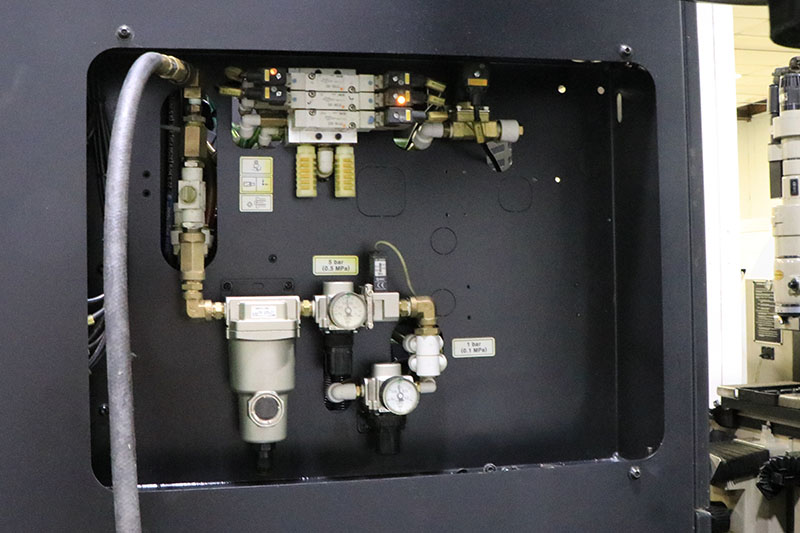

- All standard accessories

Condition

- Excellent working condition

- Fully equipped and production-ready

- Ideal for multi-axis, done-in-one machining of precision components with turning, milling, drilling, and Y-axis capability