Description

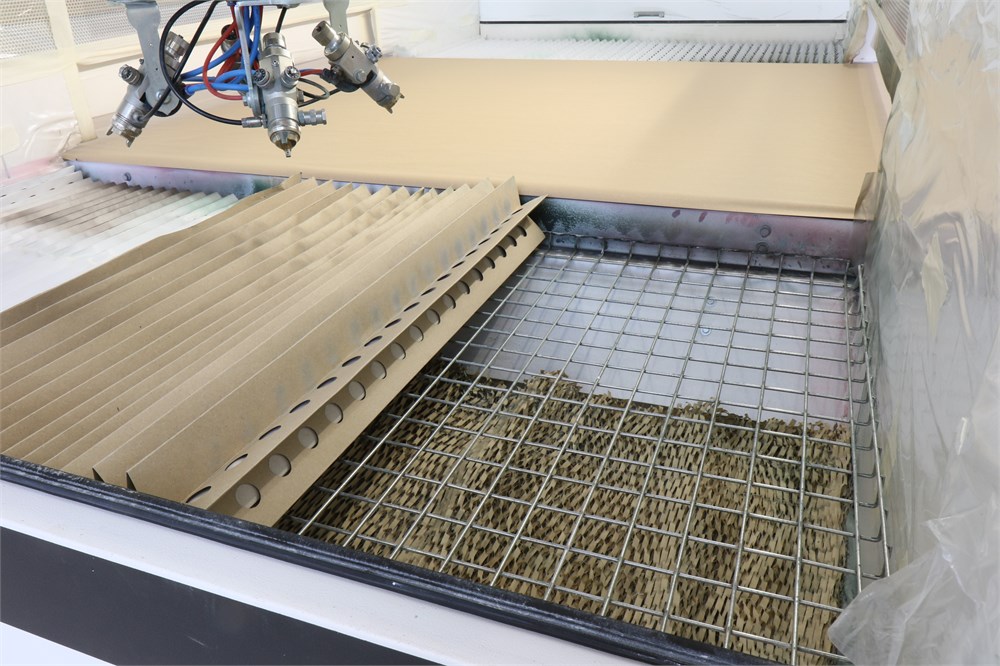

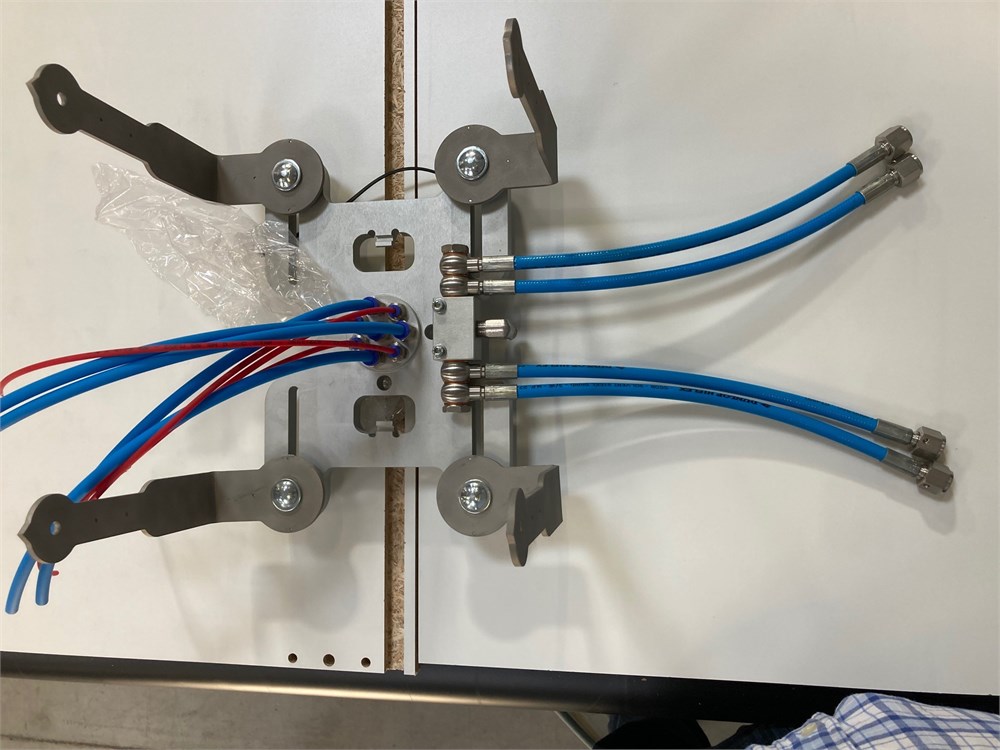

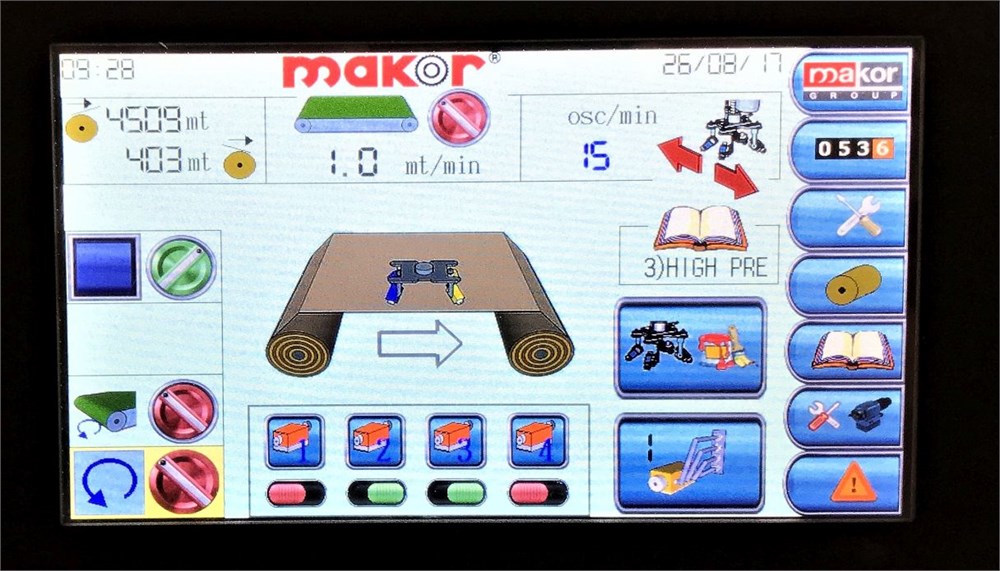

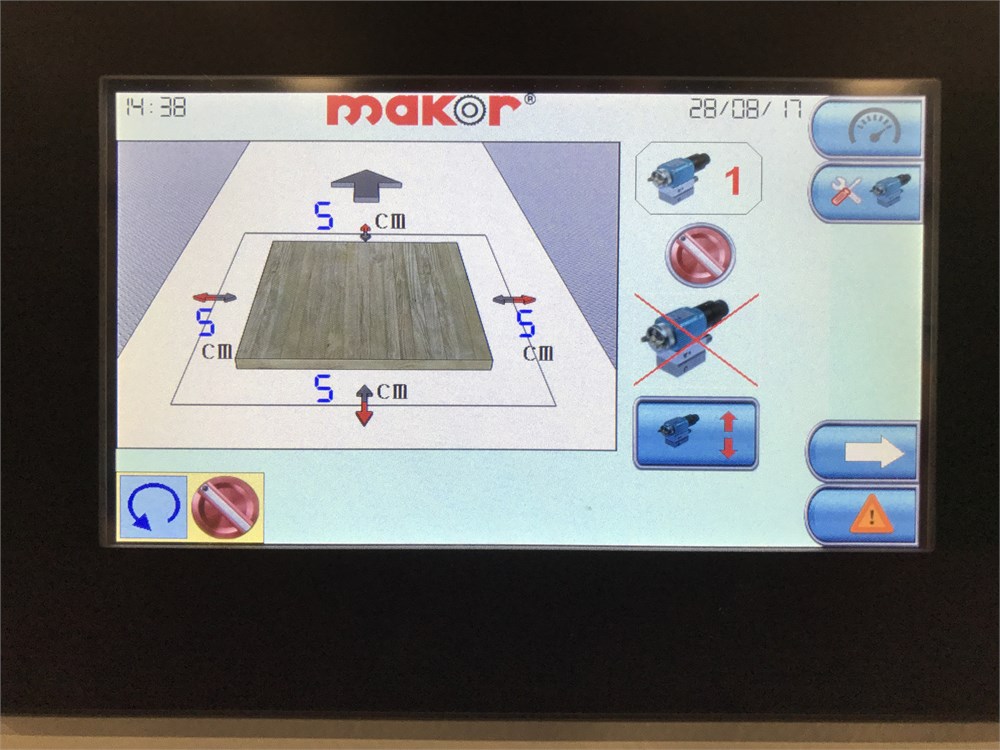

Makor “S-One C” Reciprocating Spray Machine (2018) See footprint drawing in PDF Section This machine is located in Homag Canada’s Montreal showroom. The machine was only on display and never ran any paint through it and is in great condition. Compatible with water base and/or solvent base coatings. For ideal edge coverage for painting, parts should be sprayed on both surface sides Flexibility, reliability, easy to use, combined with a limited operational cost and investment, enable S-ONE to be the ideal machine for those companies that handle low volume production applying water based or solvent based paints, or glues for veneered components or PVC. The design of the spray booth guarantees a proper control of air flows, avoiding the dispersion of the overspray to the environment. A large dimensioned filtering surface area is designed to keep exhausted particular matter in compliance with regulations. Exhaust fans can be adjusted separately to ensure maximum filter efficiency. Accessibility is permitted from both sides of the cabin for an easy maintenance. Even companies that are switching to automatic coating application for the first time can realize the advantages offered by the S ONE: higher production, paint savings, uniform coating and higher and more constant quality. Left hand orientation 1,300/51″ working panel width 60 mm/2.4″ maximum panel thickness 3.25 – 13.1 FPM feed speed 900 mm/35″ working height Three (3) independent high pressure circuits. With quick connect system for easy changing of spray gun plate. One (1) spray gun hanging plate ATEX rated motors. Able to spray solvent and water base coatings. Part recognition via 2D reading bar. IR curtain diode spacing is 12mm. Spray guns and pumps NOT included Control Systems The machine is managed by a touch screen that displays and manages the functions and working parameters in a very intuitive way. An electronic barrier reads accurately the dimensions of pieces and, through PLC, controls in real time the guns opening and closing achieving therefore high paint transference on the side to be coated. Paper Transport System The paper transport system makes the machine self-cleaning and eliminates maintenance costs. The roller replacement is quick and easy. Cleaning is not needed and there are no stop times. Spraying unit The spraying system consists of one oscillating arm with an electronically controlled drive to ensure smooth movement, providing a consistent application across entire working width.

Specifications:

Pick Up Location: Montreal, Quebec

Make: Makor

Model: S-One C

Serial Number: 16491

Year: 2018

Phase: 3 PHASE

Voltage: 480 VOLT

Estimated Dimensions: See photos and description

Estimated Weight: See photos and description

Seller Comment: Forklift onsite Seller to load onto buyers truck at no charge