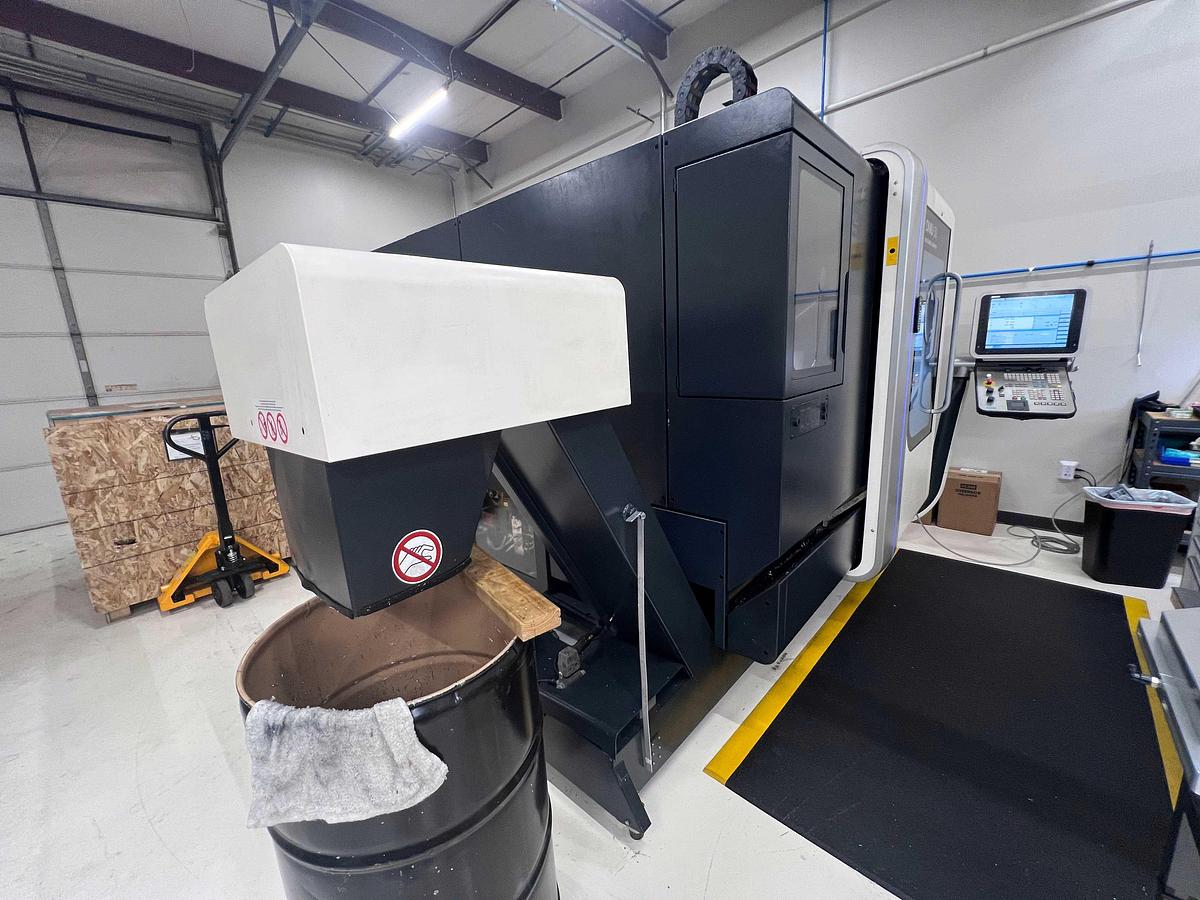

Description

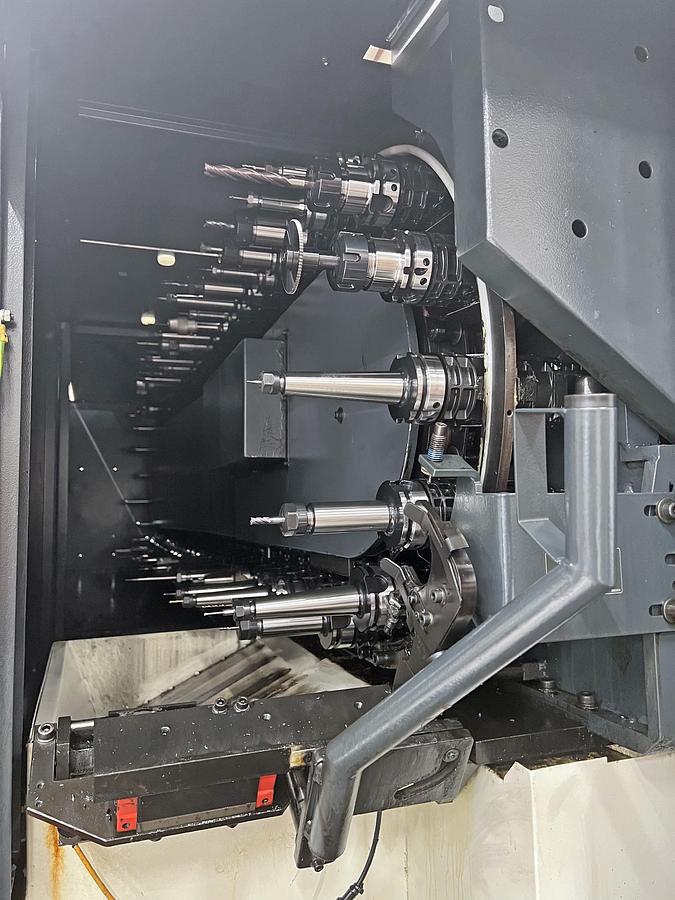

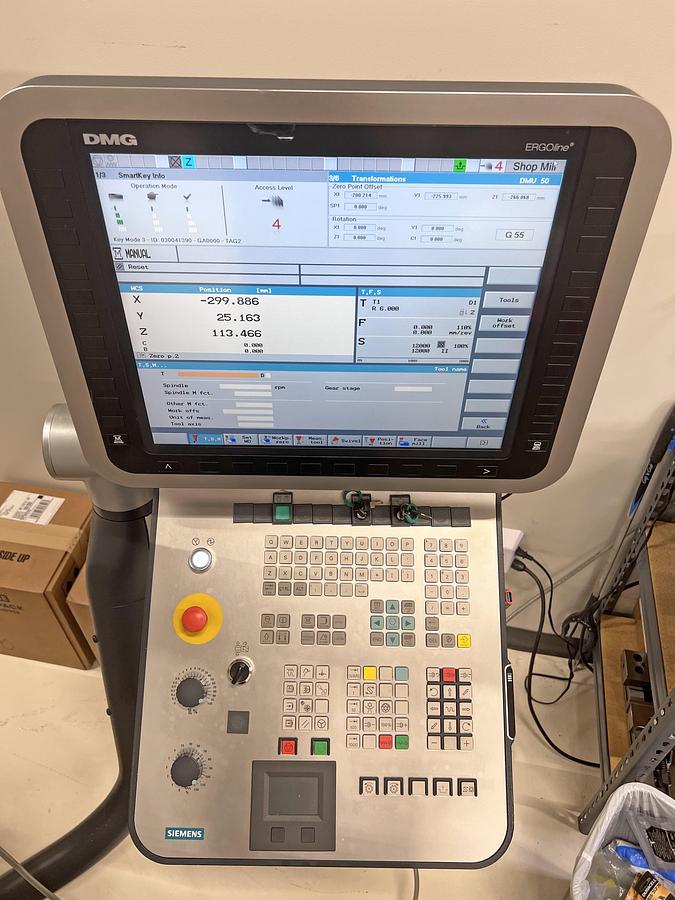

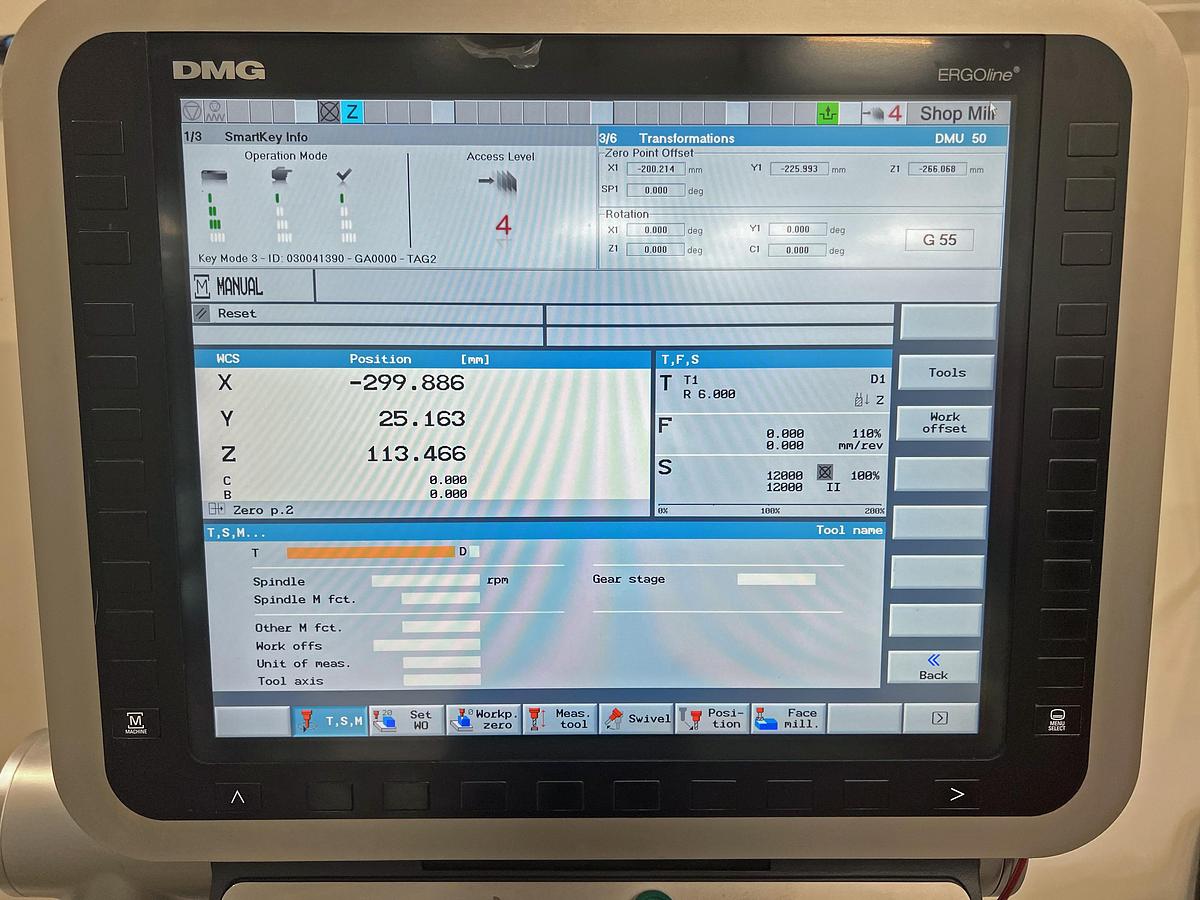

Compact, rigid, and production-ready 5-axis platform with Siemens 840D solutionline and DMG ERGOline 19″ display. Direct measuring systems on all axes, a 14,000 RPM integrated motor spindle, and automation prep (M65 interface) deliver high accuracy and lights-out capability.

Specifications

- Model/Generation: DMU 50, 2nd Generation

- Year: 2013

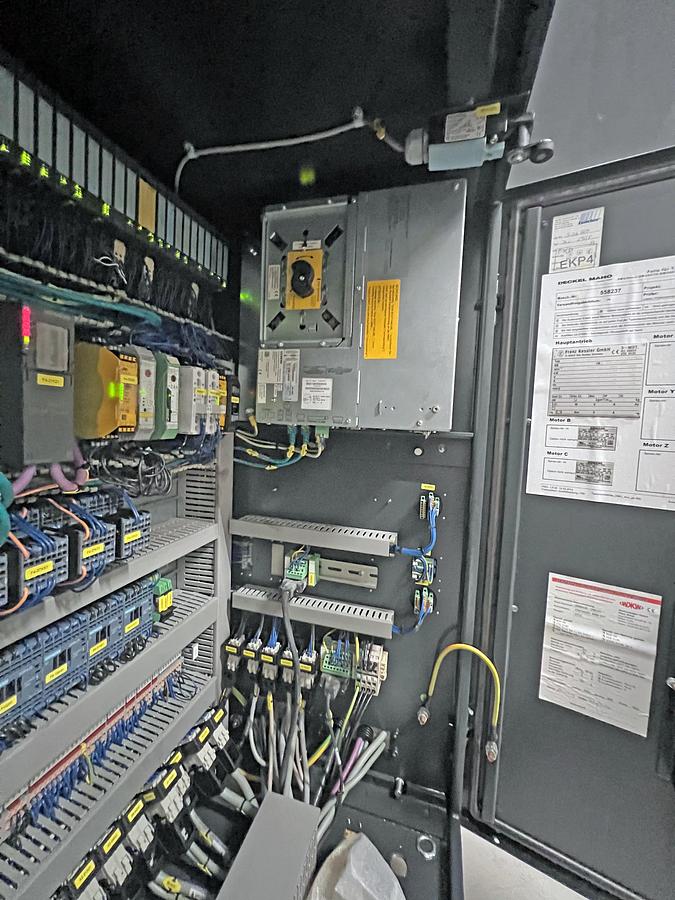

- Control: Siemens 840D solutionline with ShopMill Open; DMG ERGOline, 19″ display, DMG LIGHTline

- Spindle: Integrated motor spindle, up to 14,000 RPM, approx. 30 HP

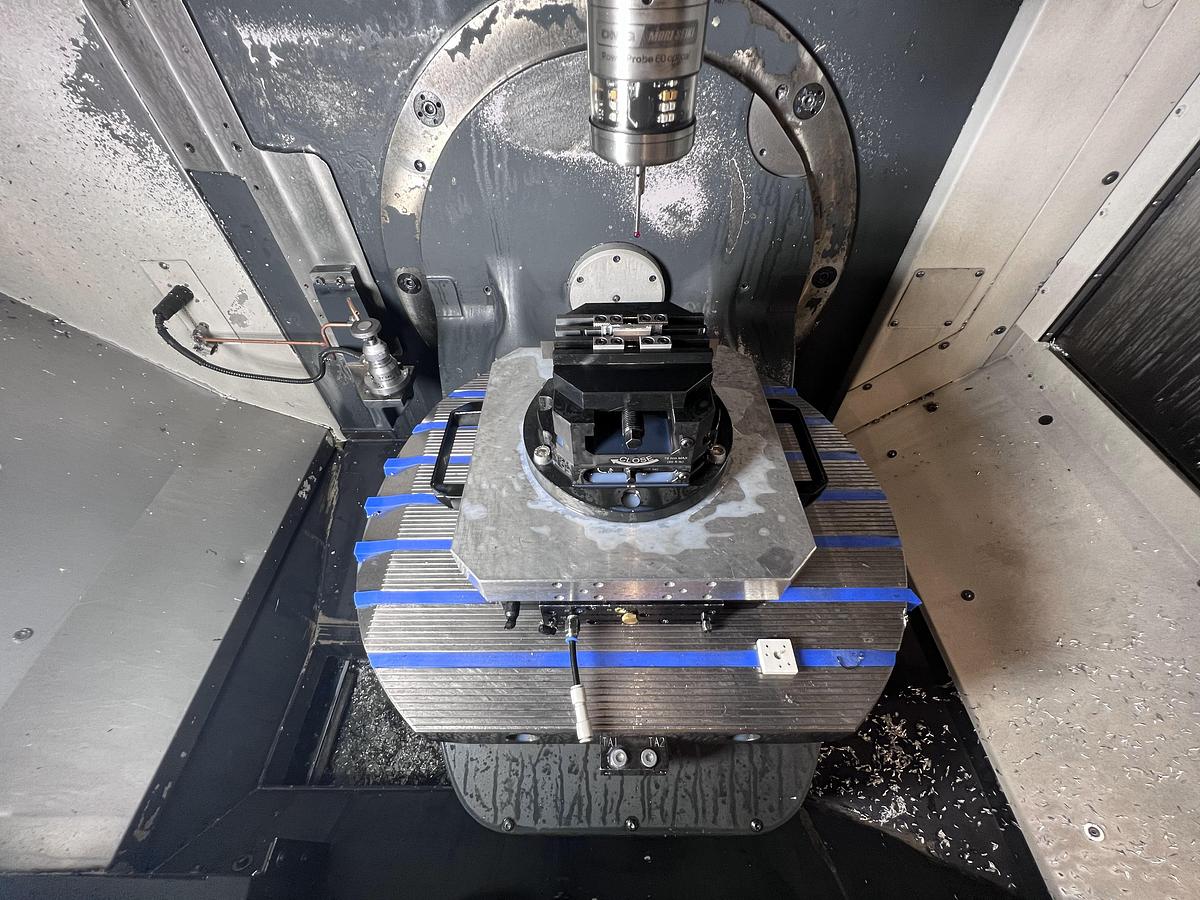

- Kinematics: Swivel rotary table (B/C) for simultaneous 5-axis machining, working-plane transformation

- Feedback Systems: HEIDENHAIN glass scales (X/Y/Z); HEIDENHAIN rotary encoders (B/C)

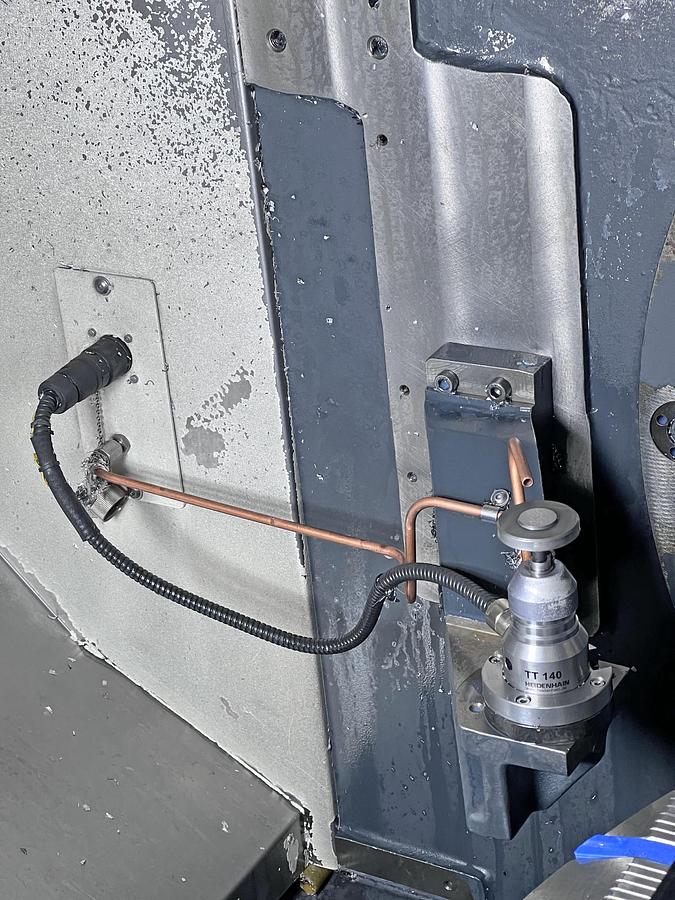

- Coolant/Chip: Internal coolant supply with paper-type filter, 600 L tank; 30 bar (435 PSI) through-spindle coolant; scraper-type chip conveyor

- Run Hours: ~8,000 spindle run hours

Equipped With

- Automation preparation via M65 interface

- Automatic side guillotine door

- Hydraulic workpiece clamping through the swivel rotary table (2 channels)

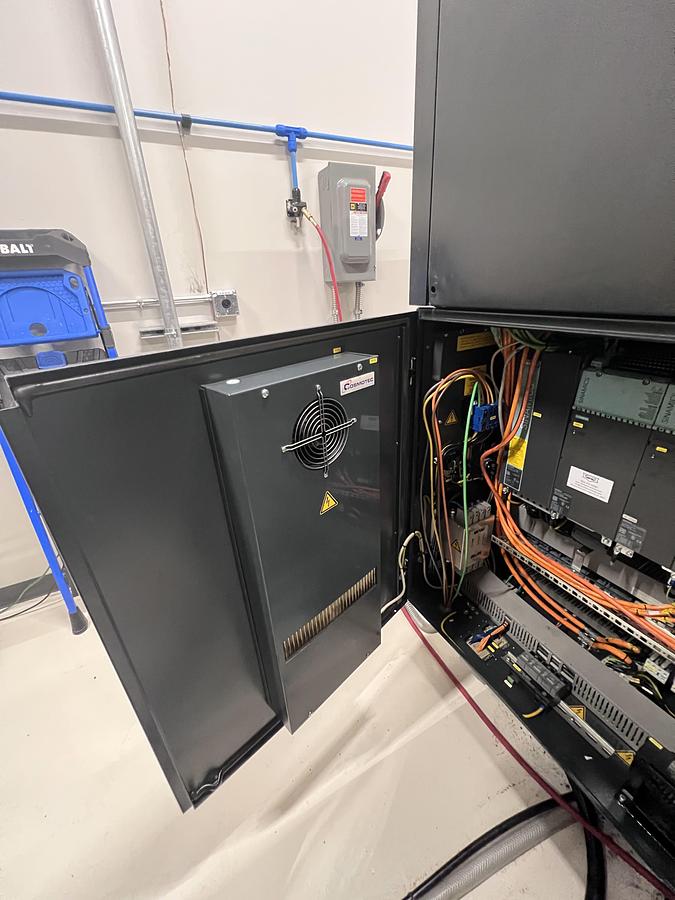

- External hydraulic control unit with electrical cabinet; one clamping circuit (2 connections)

- Renishaw OMP60 infrared touch probe (Power Probe)

- HEIDENHAIN TT 140 tool measurement & breakage control (static or rotating)

- 3D quickSET toolkit for geometric/kinematic compensation

- Spinning Visiport viewing window on front door

- Fully enclosed guarding with roof (CTS-ready)

- Rotary joint in spindle for CTS

Condition

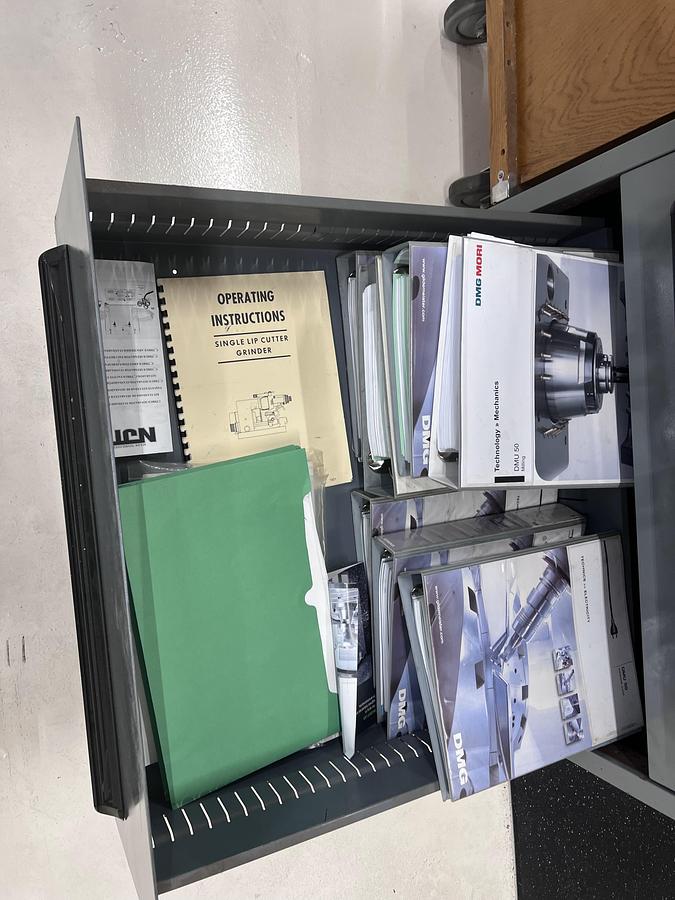

Used, clean, and fully operational. Well-optioned 2nd-gen DMU 50 with direct scales, CTS, probing, and full automation prep—ready for immediate production.