Description

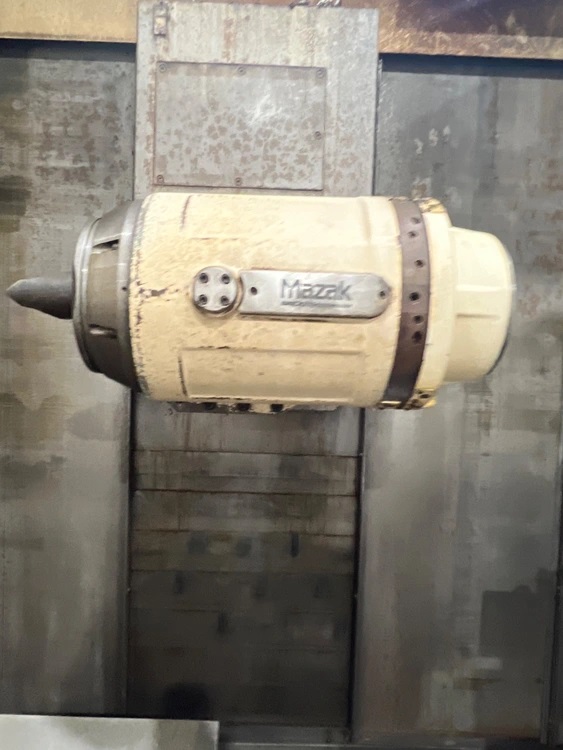

The Mazak Integrex i-400ST is a highly versatile, full 5-axis multi-tasking machine designed to deliver Mazak’s Done-In-One capability—performing turning, milling, drilling, and 5-axis machining in a single setup. Built in April 2018, this advanced machine integrates a live articulating B-axis milling spindle, sub spindle, and lower turret, supported by bar feeding, part loading, high-pressure coolant, and Mazatrol Smooth CNC Control. The result is reduced lead times, improved machining accuracy, and lower operating costs for complex parts.

Specifications

- Year: 2018 (April)

- Axes: 5 (X, Y, Z, C, B)

- Maximum Swing: 26.9″

- Maximum Turning Diameter: 26.9″

- Maximum Cutting Length: 59.8″

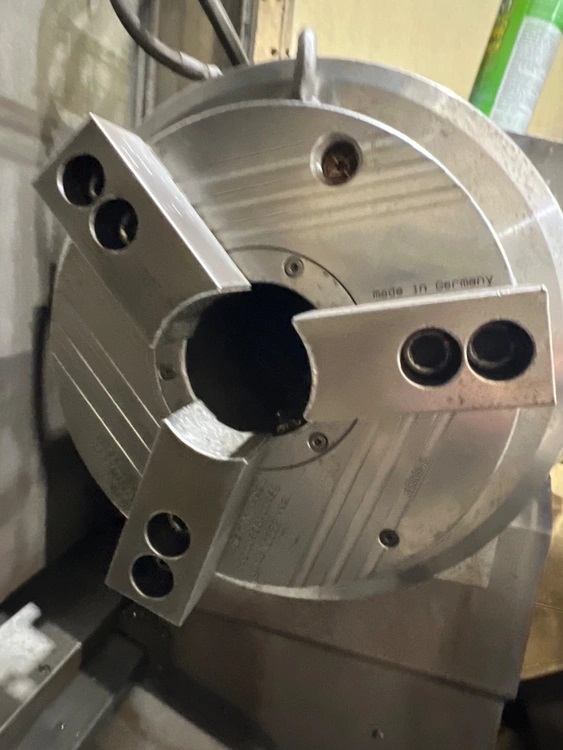

- Main Spindle:

- Chuck Size: 12″ Hydraulic

- Bore Diameter: 4.4″

- Bar Capacity: 4.0″

- Speed: 3,300 RPM

- Power: 40 HP (cont./30 min)

- Sub Spindle:

- Chuck Size: 10″ Hydraulic

- Bore Diameter: 3.58″

- Speed: 4,000 RPM

- Power: 30 HP

- W-Axis Travel: 61.96″

- Milling Spindle (B-Axis):

- Articulating Range: +210° ~ -30°

- Indexing: 240°

- Speed: 12,000 RPM

- Power: 30 HP

- Tool Interface: KM-63

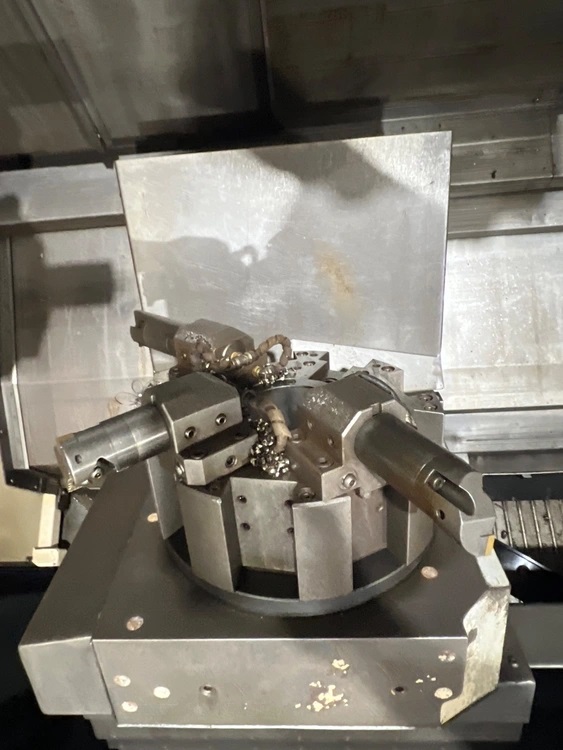

- Tooling:

- ATC Magazine Capacity: 36 tools

- Turrets: 1 lower turret with 9 stations

- Travels:

- X-Axis: 24.2″

- Y-Axis: ±4.92″

- Z-Axis: 62.4″

- Rapid Traverse Rates: X = 1969 IPM, Y = 1575 IPM, Z = 1969 IPM

- C-Axis Indexing (main & sub): 0.0001°

- Machine Dimensions: 205″ L x 110″ W x 107″ H

- Machine Weight: ~43,000 lbs

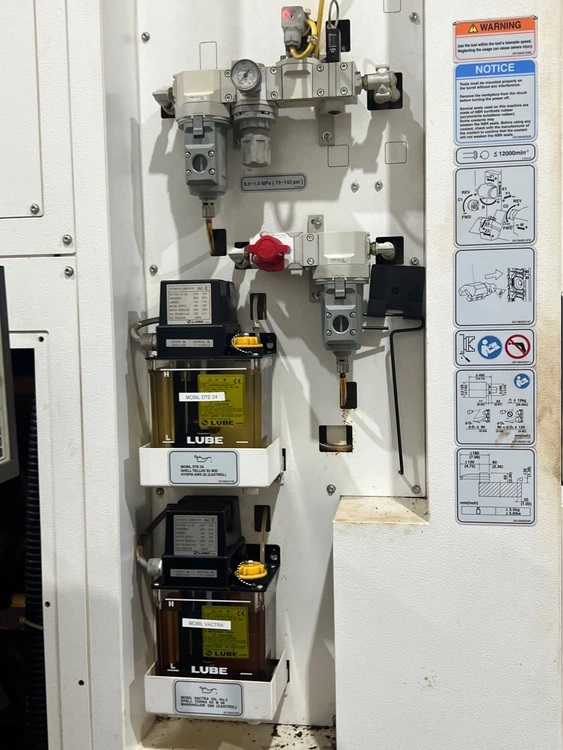

Equipped With

- Mazatrol Smooth CNC Control

- Live Articulating B-Axis Milling Spindle

- Sub Spindle with Air Chuck

- Lower Turret (9 stations)

- LNS Quick Load S3T Bar Feeder

- Parts Loader

- Chip Conveyor

- High-Pressure Coolant System

- Automatic Tool Eye for Main Spindle and Lower Turret

- Multi-Tap Transformer